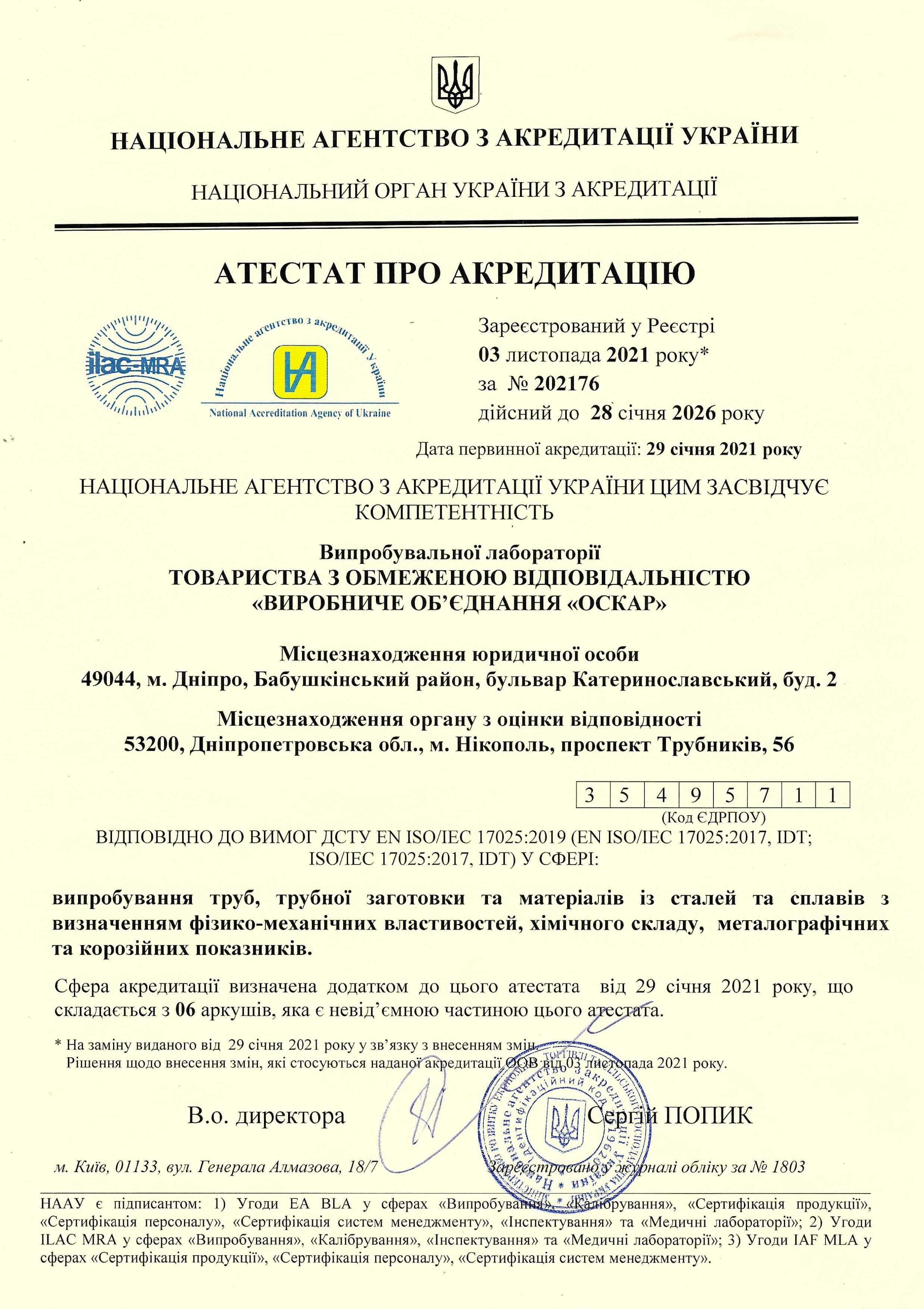

Quality

As one of the leading manufacturers of high-tech tubular products for critical working conditions in nuclear, aerospace industries, OSCAR Production Group places special emphasis on quality control of manufactured products..

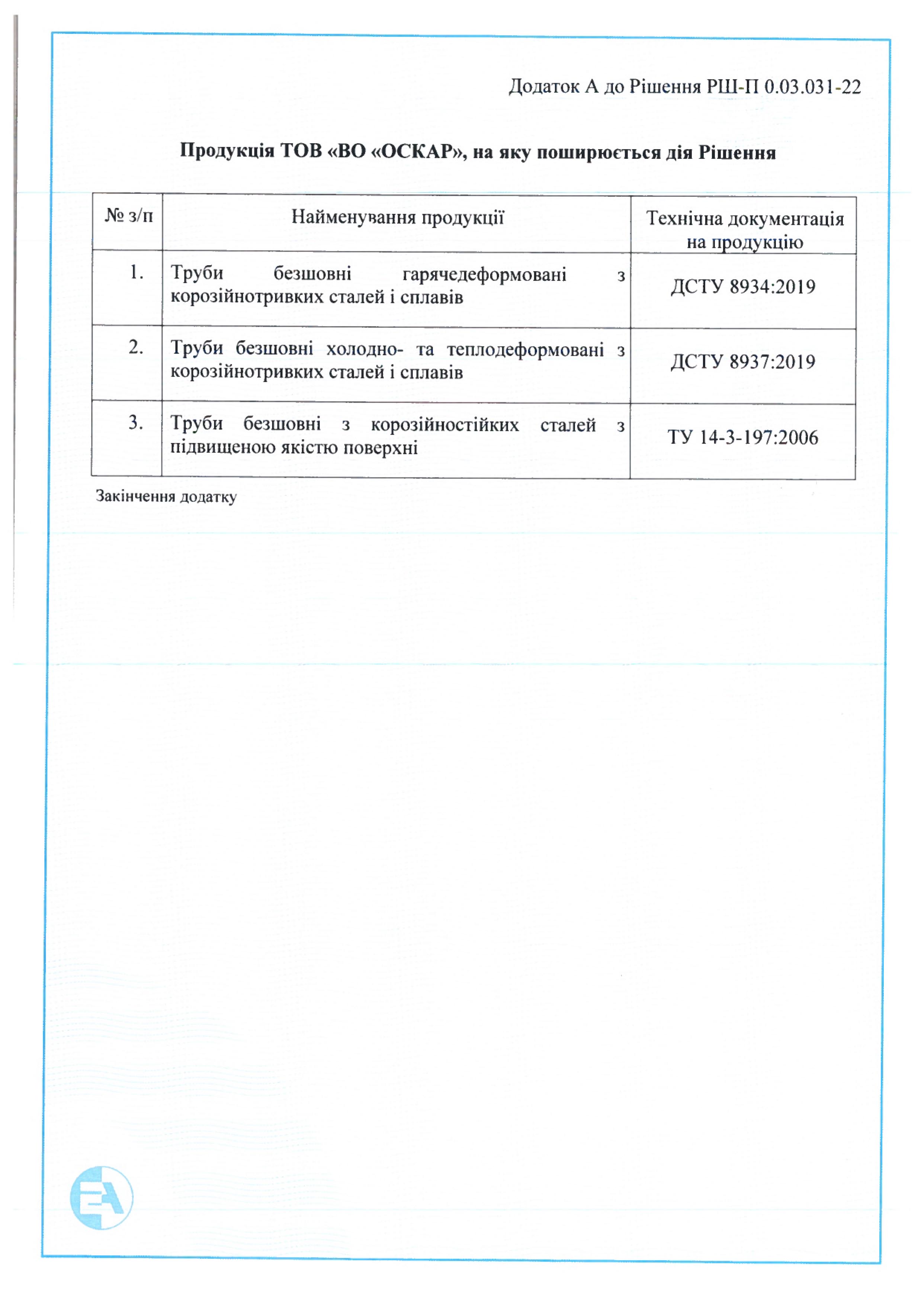

Oscar Production Group has qualified personnel (qualification is confirmed by proper accreditation centers) and all necessary technical facilities for control and testing procedures, set out in domestic and foreign standards applied to the products, manufactured at the enterprise. OSCAR Production Group has a certified central testing laboratory, a metrology laboratory, and a department of nondestructive testing of pipes.

Oscar Production Group has qualified personnel (qualification is confirmed by proper accreditation centers) and all necessary technical facilities for control and testing procedures, set out in domestic and foreign standards applied to the products, manufactured at the enterprise. OSCAR Production Group has a certified central testing laboratory, a metrology laboratory, and a department of nondestructive testing of pipes.

The quality of products is controlled at all stages - starting with the launch of production until shipping to Customer. The special technological processes are controlled with documentation of results in accordance with the direct instrumented measurement. Oscar Production Group provides the following types of tube control:

- Visual inspection of external and internal surfaces with the usage of optical facilities.

- Instrumental measurement of geometrical parameters.

- Instrumented control for estimation of the quality of tubes’ external and internal surfaces, metal denseness control, microstructure analysis, measurements of tube surface roughness and for measurements of geometrical parameters (diameter, length and wall thickness) over the entire tube length

- Control of steel grades by steeloscopes (for alloy steels) and chemical or spectral analysis.

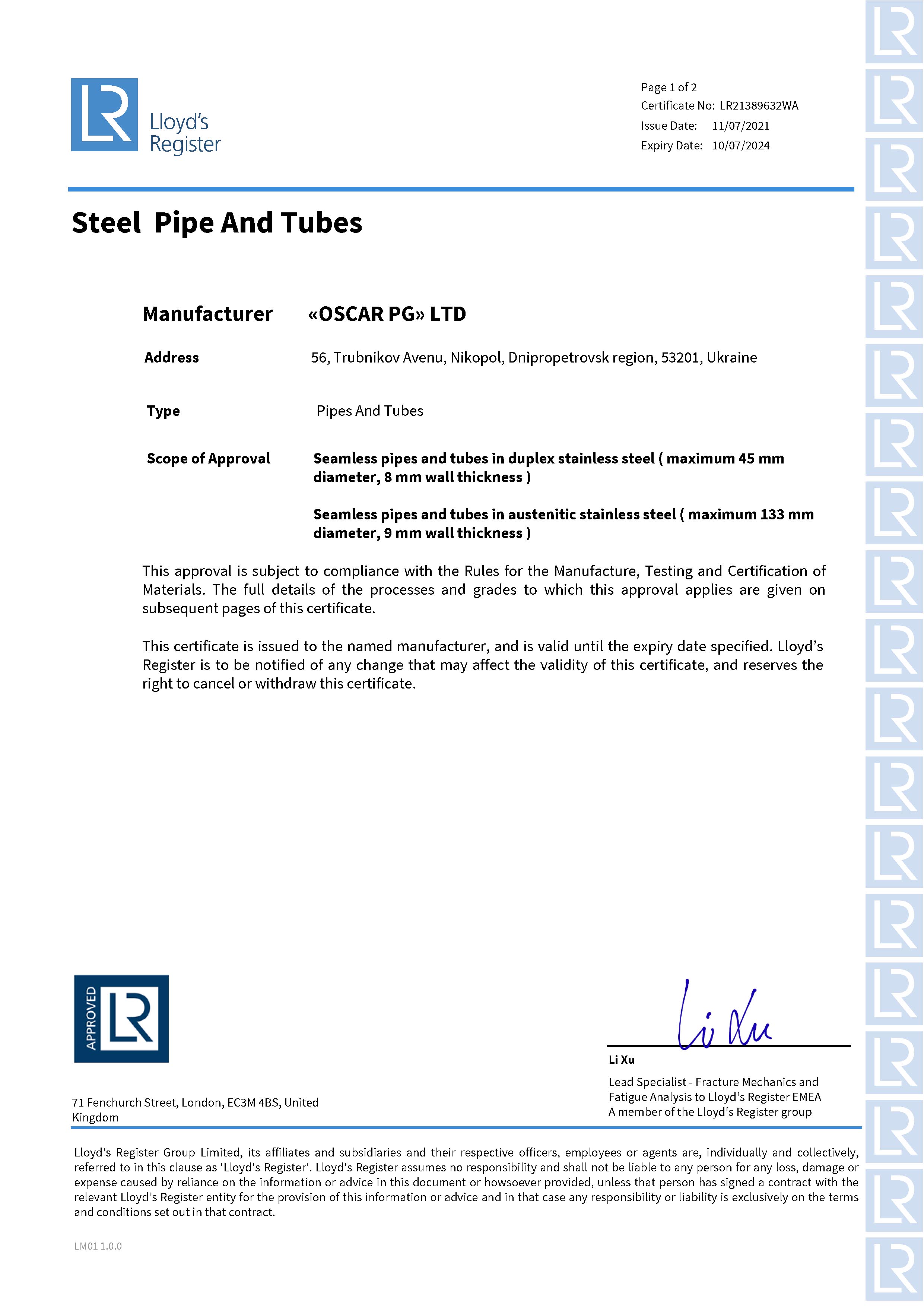

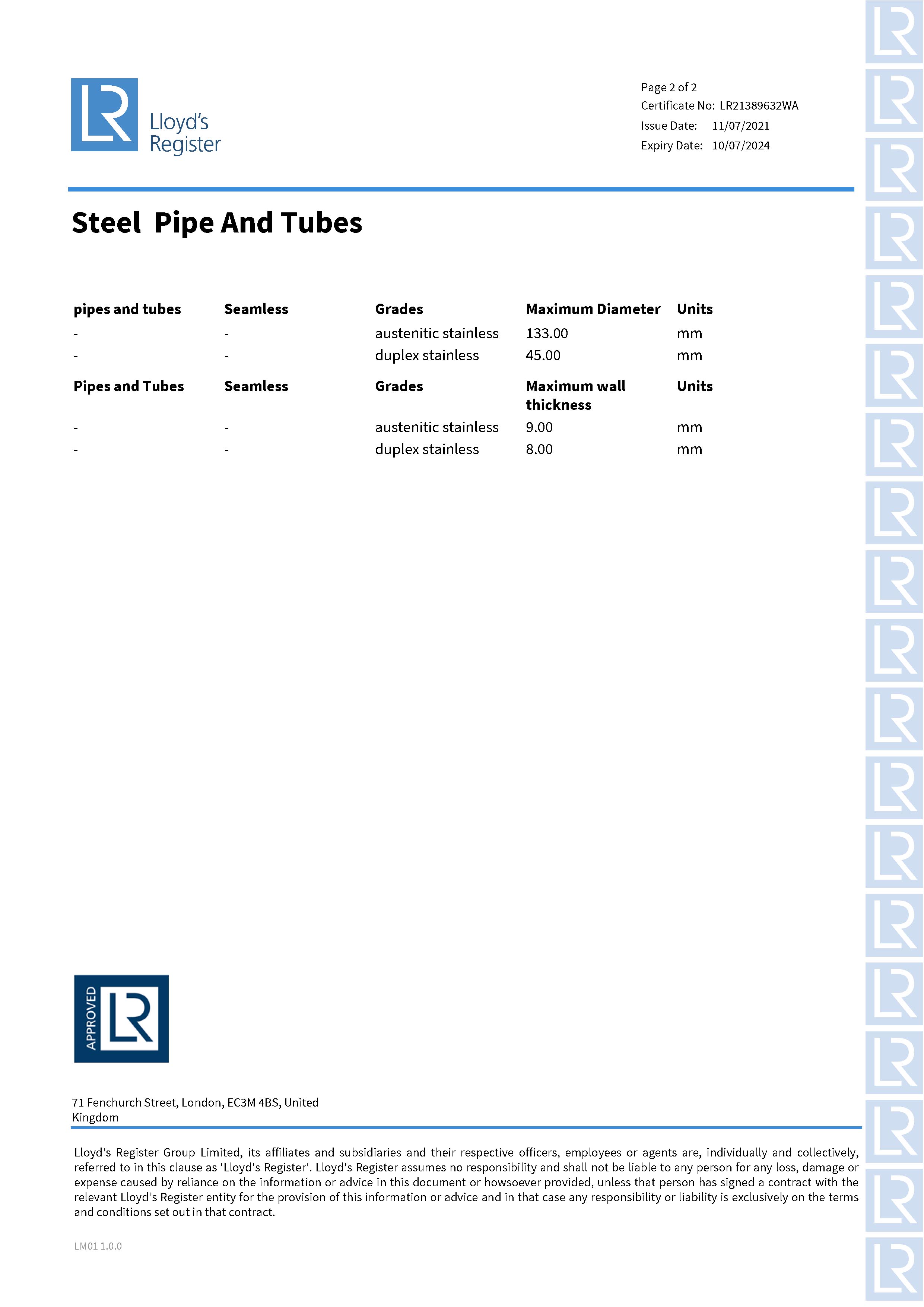

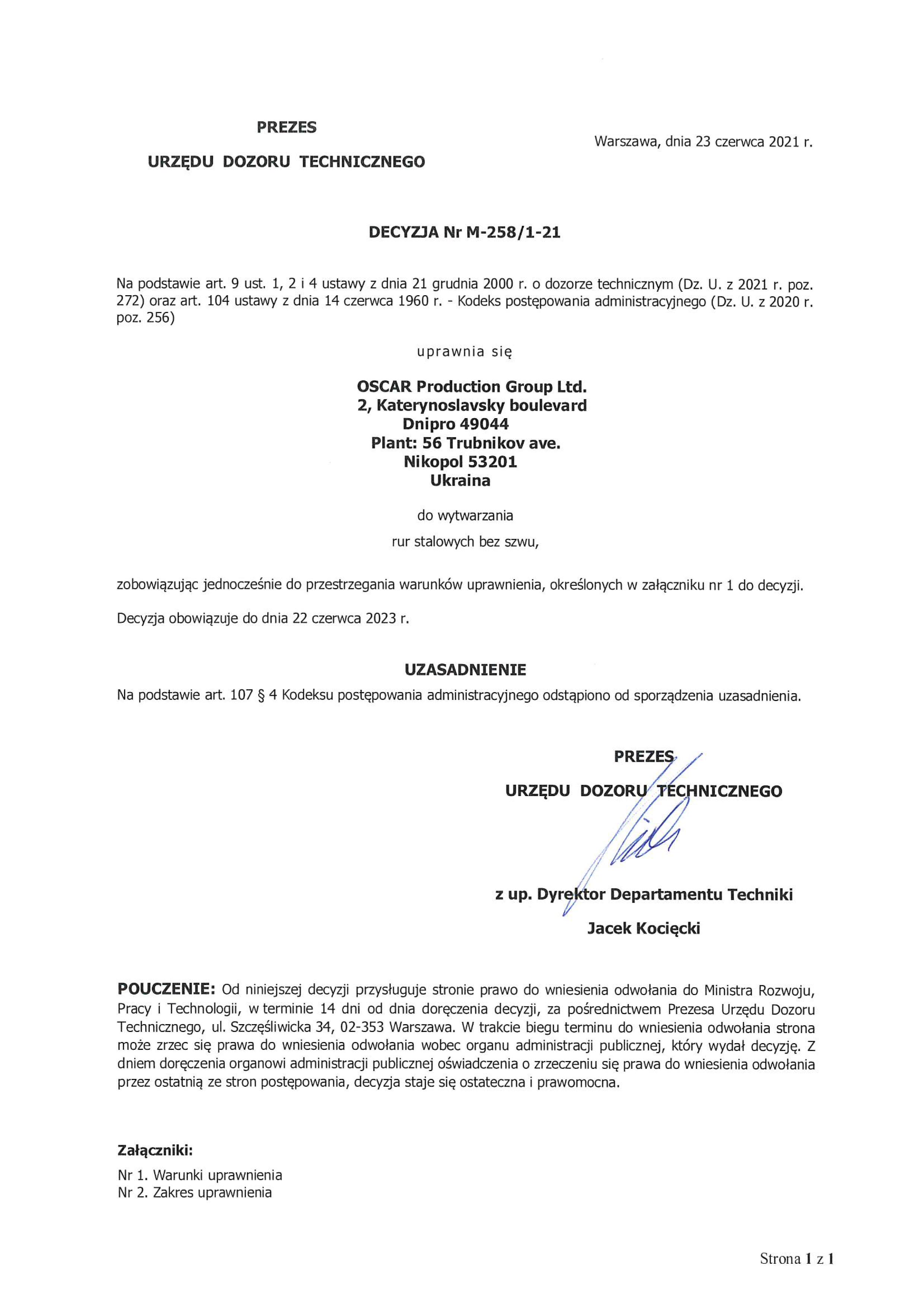

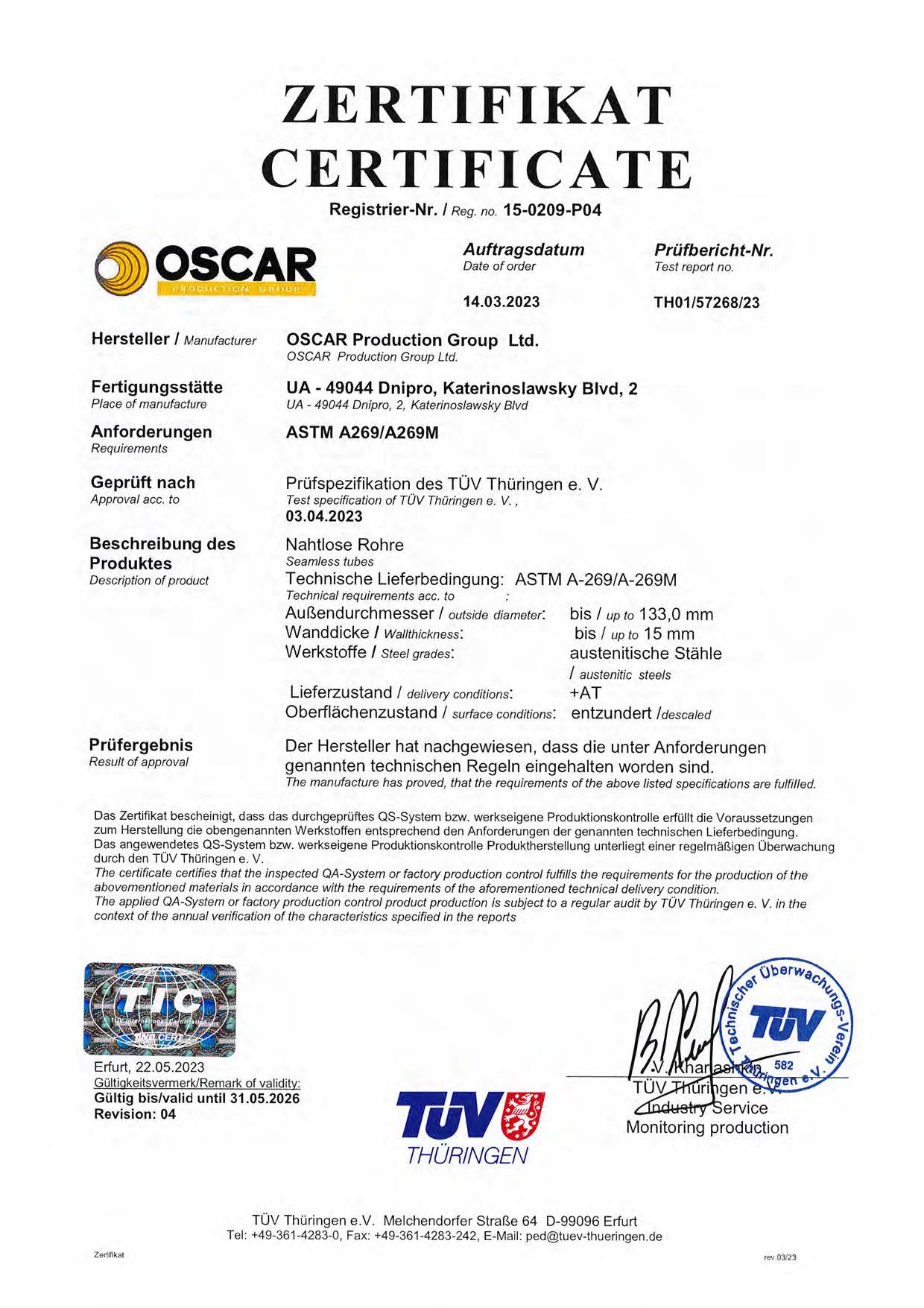

Certification of quality management system according to ISO 9001 and EN 9100 was conducted by Certification authorities TUV Thuringen and TUV Nord, experts of Technical Control Department are certified according to EN 473.